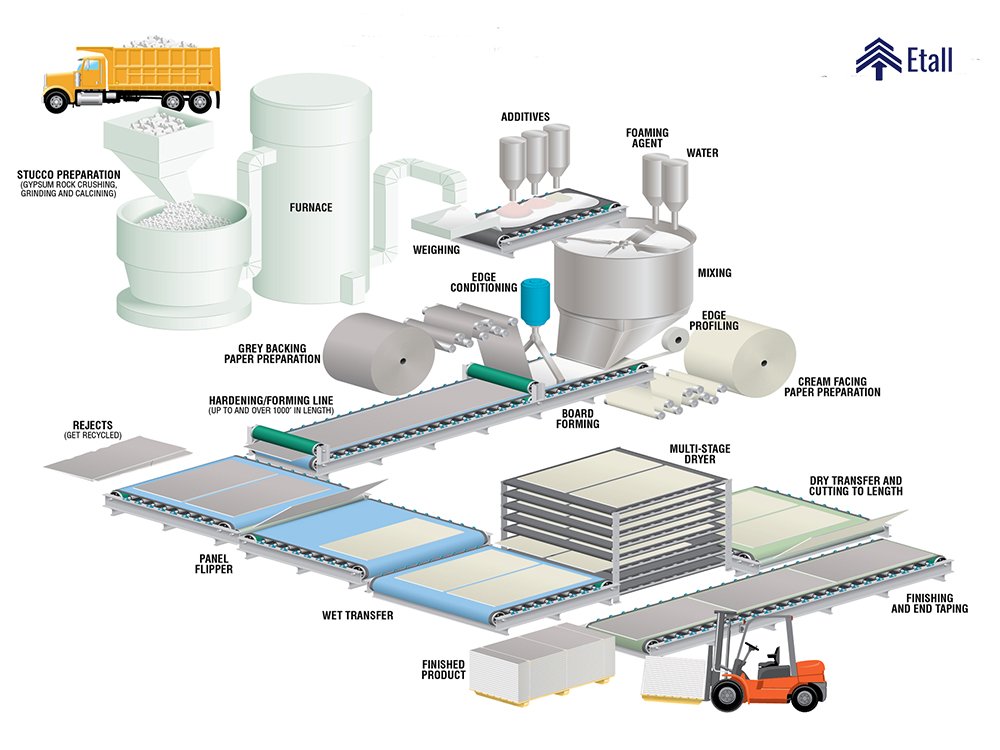

In the realm of construction materials, gypsum boards stand as a testament to precision engineering and innovative manufacturing. The production process of gypsum boards at Shandong Etall Building Materials Co.,Ltd is a meticulous journey that ensures the creation of high-quality, durable, and versatile building materials. Let’s delve into the key stages that define our gypsum board production.

Stage 1: Raw Material Selection and Preparation

Our process begins with the careful selection of raw materials, primarily gypsum and paper. Gypsum, a naturally occurring mineral, is mined and processed to create the core of the gypsum board. The gypsum is then finely ground to achieve the desired consistency. Simultaneously, paper layers are prepared to envelop the gypsum core, contributing to the board’s strength and flexibility.

Stage 2: Gypsum Core Formation

The finely ground gypsum is mixed with additives and water to form a slurry. This slurry is then poured onto a continuous sheet of paper, creating the gypsum core. As the slurry progresses, excess water is removed, and the gypsum core begins to solidify. Precision in this stage is critical to achieving the desired thickness and uniformity of the gypsum core.

Stage 3: Paper Encapsulation

The gypsum core is sandwiched between two layers of paper, forming a continuous sheet. These paper layers not only encase the gypsum but also provide additional strength, durability, and a smooth surface for finishing. The layers are firmly bonded through a combination of heat and pressure, ensuring a cohesive and resilient structure.

Stage 4: Cutting and Shaping

Once the continuous sheet is formed, it undergoes cutting and shaping processes to create individual gypsum boards of specified dimensions. Precision cutting ensures that each board meets the required standards and dimensions, contributing to the efficiency of installation on construction sites.

Stage 5: Drying and Curing

The freshly cut gypsum boards undergo a controlled drying and curing process. This stage is crucial for eliminating excess moisture, enhancing the boards’ stability, and preparing them for subsequent finishing and packaging. Our state-of-the-art facilities ensure an optimal environment for the drying and curing process.

Stage 6: Finishing and Quality Control

After the drying process, the gypsum boards move to the finishing stage. This involves sanding, beveling, and edging to achieve a smooth and refined surface. Stringent quality control measures are implemented at every step to identify and rectify any imperfections, ensuring that only flawless products leave our production facility.

Stage 7: Packaging and Distribution

The final step involves packaging the finished gypsum boards for distribution. Careful packaging preserves the integrity of the boards during transportation and handling, guaranteeing that our clients receive products of the highest quality.

At Shandong Etall Building Materials Co., Ltd, our commitment to excellence is embedded in every facet of the gypsum board production process. From raw material selection to the final product, our focus on precision, quality, and innovation ensures that our gypsum boards meet and exceed the expectations of the construction industry. Explore the possibilities with Etall Building Materials, where craftsmanship meets construction.